Cylinders

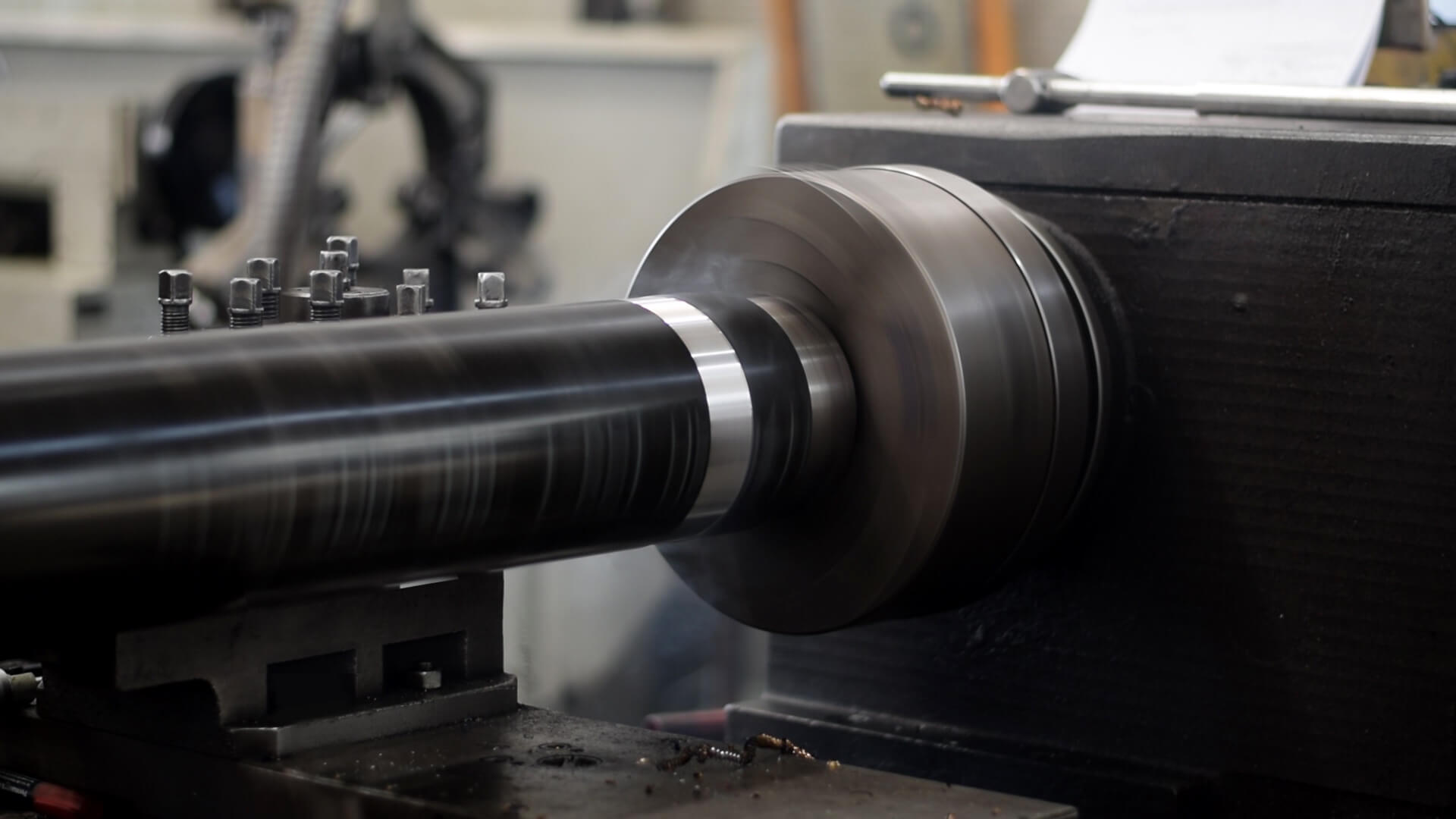

On an area of over 4500 m2 are situated machines and facilities for cutting, CNC-turning, CNC-milling, welding and inside diameter finish machining. The cylinder barrel is mostly made from seamless cold-drawn tubes suitable for skiving and roller-burnishing. In some cases the usage of welded, skived and roll-burnished tubes is also available.

A stock with high running tubes is also located at the same area. Common used steel grades of the tubes are S355 +SR as well as 20MnV6 +SR acc. to EN 10305-1.

Robot welding as well as number of semi-automatic welding devices ensures stable, high quality level of the welding seam between cylinder base (bottom) and the barrel.